Camel Component

Wire Harness

OEM Service

The OEM department specializes designing and manufacturing capacitors. We supply kinds of capacitors. Welcome to OEM services, please tell your demand, and we will feedback in 24 hours. Please contact us: ctcheam@camelcom.com.my.

OEM Service

The OEM department specializes designing and manufacturing capacitors. We supply kinds of capacitors. Welcome to OEM services, please tell your demand, and we will feedback in 24 hours. Please contact us: ctcheam@camelcom.com.my.

| i. PST. Metallized polyphenylene sulphine (PPS) capacitor - axial lead |

| ii. PSC. Metallized polyphenylene sulphine (PPS) capacitor - encapsulated |

ii. PSC. Metallized Polyphenylene Sulphine (PPS) Capacitor - Encapsulated

PSC are constructed with metallized polyphenylene sulphide (PPS) film dielectric, encapsulated in plastic case and epoxy resin end seal, tinned copper wire. They are ideal for use in high temperature resistance equipments.

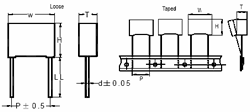

Drawing:

Outline Drawing |

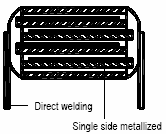

Construction |

Appearance |

|

|

|

Features:

- Good solderability

- Miniature size and light weight

- High stability of capacitance and DF versus high temperature

- Non-inductive construction

Specification:

- Operating temperature: -55 ~125 ℃

- Capacitance range: 0.001µF~3.3µF

- Capacitance tolerance: ±5%(J), ±10%(K), ±20%(M)

- Rated voltage: 63VDC, 100VDC, 250VDC

- Dissipation factor: C≦1µ F≦0.3% C>1µ F≦0.5% Max at 1KHZ 25℃

- Insulation resistance:

- >3500MΩ(C≦0.33µF; VR=50V)

- >7500MΩ(C≦0.33µF; VR≦100)

- >2500s (C>0.33µF; VR>100V)

- >1250s (C>0.33µF; VR≦100V)

Performance:

| Test Characteristics | Test Methods JIS C 5102 | Performance |

| Withstand voltage: Between terminals | Apply 1.4 times of rated voltage for 2 sec. Charge discharge current must be 1A max | Shall be no abnormality |

| Withstand voltage: Between terminals & enclosure | Apply 2.0 times of rated voltage for 1 to 5 sec | Shall be no abnormality |

| Insulation resistance: Between terminals | Apply rated voltage ±15% for 60 sec. when rated voltage under 100V. Apply 100V ±15% when rated voltage from 100V to 500V at 20℃ | ≤0.33µF ≧7500MΩ >50V ≧3750MΩ ≤100V >0.33µF ≧2500s >100V ≧1250s ≤100V |

| Insulation resistance: Between terminals & enclosure | ||

| Heat proof: Insulation resistance at 100℃ | Testing temperature: 100±2℃ | ≤0.33µF ≧3750MΩ >100V ≧1875MΩ ≤100V >0.33µF ≧1250s >100V ≧625s ≤100V |

| Heat proof: Rate of variation of capacitance at 100℃ | Within +5% 12% of the value before test | |

| Humidity test: Appearance | Temperature: 40±2 ; Humidity: 90-95% RH Testing time: 500 +24 -0 Hrs. Apply voltage: rated voltage. After testing, leave it for about 16 Hrs. at standard condition Withstand voltage is 125% rated voltage, 60 sec. |

Shall be no abnormality |

| Humidity test: Withstand voltage | Shall be no abnormality | |

| Humidity test: Insulation resistance | ≤0.33µF ≧3750MΩ >100V ≧1875MΩ ≤100V >0.33µF ≧1250s >100V ≧625s ≤100V |

|

| Humidity test: Dissipation factor | C≤1µF ≤0.003; C>1µF ≤0.005; | |

| Humidity test: Rate of variation capacitance | Within ±5% of the value before test | |

| Reference Standard | GB 7332 (IEC 60384-20)/ JIS C 5102 | |

Dimensions:

63VDC |

||||||

| Part No. | Cap.(µF) |

Dimensions(mm) |

||||

W |

H |

T |

P |

dФ |

||

| PSC223□1J-7-5□□□□□ | 0.022 |

7.2 |

6.5 |

2.5 |

5.0 |

0.6 |

| PSC333□1J-7-5□□□□□ | 0.033 |

7.2 |

7.5 |

3.5 |

5.0 |

0.6 |

| PSC473□1J-7-5□□□□□ | 0.047 |

7.2 |

7.5 |

3.5 |

5.0 |

0.6 |

| PSC683□1J-7-5□□□□□ | 0.068 |

7.2 |

9.5 |

4.5 |

5.0 |

0.6 |

| PSC104□1J-7-5□□□□□ | 0.10 |

7.2 |

10.0 |

5.0 |

5.0 |

0.6 |

| PSC154□1J-7-5□□□□□ | 0.15 |

7.2 |

11.0 |

6.0 |

5.0 |

0.6 |

| PSC224□1JA3A0□□□□□ | 0.22 |

13.0 |

11.0 |

5.0 |

10.0 |

0.6 |

| PSC334□1JA3A0□□□□□ | 0.33 |

13.0 |

12.0 |

6.0 |

10.0 |

0.6 |

| PSC474□1JA8A5□□□□□ | 0.47 |

18.0 |

12.0 |

6.0 |

15.0 |

0.6 |

| PSC684□1JA8A5□□□□□ | 0.68 |

18.0 |

13.5 |

7.5 |

15.0 |

0.6 |

| PSC105□1JA8A55□□□□□ | 1.0 |

18.0 |

14.5 |

8.5 |

15.0 |

0.6 |

| PSC155□1JB6B2□□□□□ | 1.5 |

26.5 |

16.0 |

7.0 |

22.5 |

0.6 |

| PSC225□1JB6B2□□□□□ | 2.2 |

26.5 |

17.0 |

8.5 |

22.5 |

0.6 |

| PSC335□1JB6B2□□□□□ | 3.3 |

26.5 |

20.0 |

11.0 |

22.5 |

0.6 |

100VDC |

||||||

| Part No. | Cap.(µF) |

Dimensions(mm) |

||||

W |

H |

T |

P |

dФ |

||

| PSC682□2A-7-5□□□□□ | 0.0068 |

7.2 |

6.5 |

2.5 |

5.0 |

0.6 |

| PSC103□2A-7-5□□□□□ | 0.010 |

7.2 |

7.5 |

3.5 |

5.0 |

0.6 |

| PSC153□2A-7-5□□□□□ | 0.015 |

7.2 |

7.5 |

3.5 |

5.0 |

0.6 |

| PSC223□2A-7-5□□□□□ | 0.022 |

7.2 |

9.5 |

4.5 |

5.0 |

0.6 |

| PSC333□2A-7-5□□□□□ | 0.033 |

7.2 |

10.0 |

5.0 |

5.0 |

0.6 |

| PSC473□2A-7-5□□□□□ | 0.047 |

7.2 |

11.0 |

6.0 |

5.0 |

0.6 |

| PSC683□2A-7-5□□□□□ | 0.068 |

7.2 |

9.0 |

4.0 |

5.0 |

0.6 |

| PSC104□2AA3A0□□□□□ | 0.10 |

13.0 |

11.0 |

5.0 |

10.0 |

0.6 |

| PSC154□2AA3A0□□□□□ | 0.15 |

13.0 |

12.0 |

6.0 |

10.0 |

0.6 |

| PSC224□2AA8A5□□□□□ | 0.22 |

18.0 |

12.0 |

6.0 |

15.0 |

0.6 |

| PSC334□2AA8A5□□□□□ | 0.33 |

18.0 |

13.5 |

7.5 |

15.0 |

0.6 |

| PSC474□2AA8A5□□□□□ | 0.47 |

18.0 |

14.5 |

8.5 |

15.0 |

0.6 |

| PSC684□2AB6B2□□□□□ | 0.68 |

26.5 |

16.0 |

7.0 |

22.5 |

0.6 |

| PSC105□2AB6B2□□□□□ | 1.0 |

26.5 |

17.0 |

8.5 |

22.5 |

0.6 |

| PSC155□2AB6B2□□□□□ | 1.5 |

26.5 |

18.5 |

11.0 |

22.5 |

0.6 |

250VDC |

||||||

| Part No. | Cap.(µF) |

Dimensions(mm) |

||||

W |

H |

T |

P |

dФ |

||

| PSC102□2E-7-5□□□□□ | 0.0010 |

7.2 |

6.5 |

2.5 |

5.0 |

0.6 |

| PSC152□2E-7-5□□□□□ | 0.0015 |

7.2 |

7.5 |

3.5 |

5.0 |

0.6 |

| PSC222□2E-7-5□□□□□ | 0.0022 |

7.2 |

7.5 |

3.5 |

5.0 |

0.6 |

| PSC332□2E-7-5□□□□□ | 0.0033 |

7.2 |

9.5 |

4.5 |

5.0 |

0.6 |

| PSC472□2E-7-5□□□□□ | 0.0047 |

7.2 |

9.5 |

4.5 |

5.0 |

0.6 |

| PSC682□2E-7-5□□□□□ | 0.0068 |

7.2 |

10.0 |

5.0 |

5.0 |

0.6 |

| PSC103□2E-7-5□□□□□ | 0.010 |

7.2 |

11.0 |

6.0 |

5.0 |

0.6 |

| PSC153□2EA3A0□□□□□ | 0.015 |

13.0 |

9.0 |

4.0 |

10.0 |

0.6 |

| PSC223□2EA3A0□□□□□ | 0.022 |

13.0 |

11.0 |

5.0 |

10.0 |

0.6 |

| PSC333□2EA3A0□□□□□ | 0.033 |

13.0 |

12.0 |

6.0 |

10.0 |

0.6 |

| PSC473□2EA8A5□□□□□ | 0.047 |

18.0 |

11.0 |

5.0 |

15.0 |

0.6 |

| PSC683□2EA8A5□□□□□ | 0.068 |

18.0 |

12.0 |

6.0 |

15.0 |

0.6 |

| PSC104□2EA8A5□□□□□ | 0.10 |

18.0 |

13.5 |

7.5 |

15.0 |

0.6 |

| PSC154□2EA8A5□□□□□ | 0.15 |

18.0 |

14.5 |

8.5 |

15.0 |

0.6 |

| PSC224□2EB6B2□□□□□ | 0.22 |

26.5 |

16.0 |

7.0 |

22.5 |

0.6 |

| PSC334□2EB6B2□□□□□ | 0.33 |

26.5 |

17.0 |

8.5 |

22.5 |

0.6 |

| PSC474□2EB6B2□□□□□ | 0.47 |

26.5 |

20.0 |

11.0 |

22.5 |

0.6 |

Film

home

home contact us

contact us about us

about us